In February of 2013 I purchased a Ducati wheel off eBay in the hopes of doing whatever it takes to mount it on my RC30. A lot of water went under the bridge since I bought this wheel, but I finally found the time to do it.

The wheel I started with is a stock 17" x 5 1/2" wheel from a 2006 Ducati 1000cc Uglistrada. These wheels are nothing special, just cast aluminum, no fancy forging or scary magnesium alloy. The wheel will be getting powder coated white when I get the time.

Don't quote me on this but I think the Ducati monster (S2R/S4R) is the same wheel. Later single sided Ducati wheels are totally different. They also have a much larger bore through them. I have no idea if they are suitable for conversion for use on an RC30. There are other Ducati single sided small bore wheels but you are, as with everything else, on your own as to whether they will work.

As a side note this wheel takes an 8.3mm diameter tire valve stem, not what I am accustomed to on most every other non-Italian bike. If you need a valve stem then you should get a genuine Bridgeport forged item. The following Bridgeport part numbers are for the 83 degree version that comes standard with the Ducati wheels and are good for > 210 km/hr.

Don't buy a straight stem. It will not clear the pro-squat linkage.40 450 1501 - Bare40 450 1535 - Silver40 450 1539 - Red40 450 1533 - Black40 450 1534 - Gold40 450 1527 - Blue

That is one fugly motorcycle. The only thing worth saving is the wheel.

Here We Go !

Initial Evaluation

About the only thing that makes this wheel swap appear easy is that the spacer taper, wheel pin diameter and the wheel pin spacing & quantity are the same as the Honda Elf design. Looks like the wheel swap should be fairly easy doesn't it? There are four major problems with fitting this wheel though. I will go through them one by one so everyone understands.

Problem 1 - The wheel bore for the axle is smaller than the Honda wheel and needs to be bored out. This is a precision machining job that requires some jigging and set up that you have got to trust the machinist on.

Problem 2 - The wheel offset is incorrect. My measurements taken using reasonably precise instruments result in a spacer being needed behind the Ducati wheel to get the wheel centerline to match Honda's. If you elect to NOT install a spacer your tire will most likely hit the chain, swingarm and unobtanium inner fender on the port side. Even with a spacer the wheel comes quite close to the swingarm as the curve of the swingarm and the smaller 17" wheel radius make for a tight fit.

The spacer dimension I calculated was 2.95mm. I elected to use a 1/8" spacer (3.175mm). I am OK with moving the wheel a hair further away from the swingarm and chain. In reality the 0.009" is effectively nothing.

Problem 3 - The thickness of the Ducati hub is more than the Honda wheel. This is a pretty major issue that is compounded by the fact that the spacer (Problem 2) also adds to the hub thickness. The problem is that the centerlock spacer (gold aluminum thing with the taper under the castellated nut) will no longer engage on the end of the axle. If you were a fool and ignored this you could actually get the spacer and a nut on the axle but you could not get a cotter/split pin in as the nut does not go on far enough. My solution was making a custom centerlock spacer that will both engage the axle and allow room for a cotter pin using the standard Honda castellated nut.

Problem 4 - The tire valve stem hits the pro-squat linkage. There are a few things that can be done off the top of my head.

1. Rotate the linkage on the splines for more clearance.2. File a bit of the the 83 degree valve stem off.3. File a bit off the linkage arm.4. Machine the wheel's valve boss down a bit.5. Make a custom tire valve stem.5. Make a custom narrow link for the pro-squat linkage.

This does alter the geometry of the pro-squat linkage a bit, but for the average guy (me) it won't be noticed. Keep in mind that all racers took the linkage off except for a link to transfer brake torque to the swingarm (not the frame). Doing a one spline relocation also rotates the brake caliper clockwise on the axle looking from the starboard side. This moves the brake line a small amount, but it was negligible. I'm happy I didn't have to go berserk on anything to make it work.

The clearance between the pro-squat linkage and the five Ducati wheel spokes is also increased by re-indexing the arm. Clearance is about 4mm prior to doing the valve stem fix. Though I don't show it, after re-indexing it is plenty.

.jpg?timestamp=1711144305509)

.jpg?timestamp=1711144305509)

Problem 5 - Wait... you said four problems! Yes, I did, but problem 2 of adding a spacer results in the wheel pins (that transfer some of the engine torque, bike weight, cornering loads) needing replacement. I am sure some people don't install custom wheel pins but I did because it just feels right. Since I wanted to retain the option of easily popping on the 18" Honda wheel my spacer will go outside the shoulder of the pins. Doing this required me to have four pins made that were 1/8" longer on the pointy side to give a similar engagement with the wheel. My spacer just sits in place, located by the wheel pins. The wheel itself sandwiches the spacer in place. You could put the pins on top of the wheel spacer but the underside/threaded part of the pins must/should be extended by the 1/8" to maintain a proper press fit depth.

Solid Modeling and Fabrication

Back when I purchased the wheel I did do a lot of the solid modeling of the components. In 2024 I resurrected these models, re-verified them dimensionally and fine tuned my designs. I looked at a few options but only show what I ultimately ended up doing.

I will be installing a 170/60-17 tire. A 180 section (some say 190) is fine on the 5.5" wheel itself but will not clear on my bike. Some 170 tires are closer to 180 so I will be checking O/A tire widths before purchasing. My Honda 18" wheel has a first generation 170/60-18 Dunlop Roadsmart on it and it comes in at 178.5 wide. The Roadsmart hits the swingarm, chain and inner fender. My experience with Dunlop is that they do run nearly a size (10mm) wider than advertised. I had an old 170 Dunlop from the 90's and it was 182mm wide!

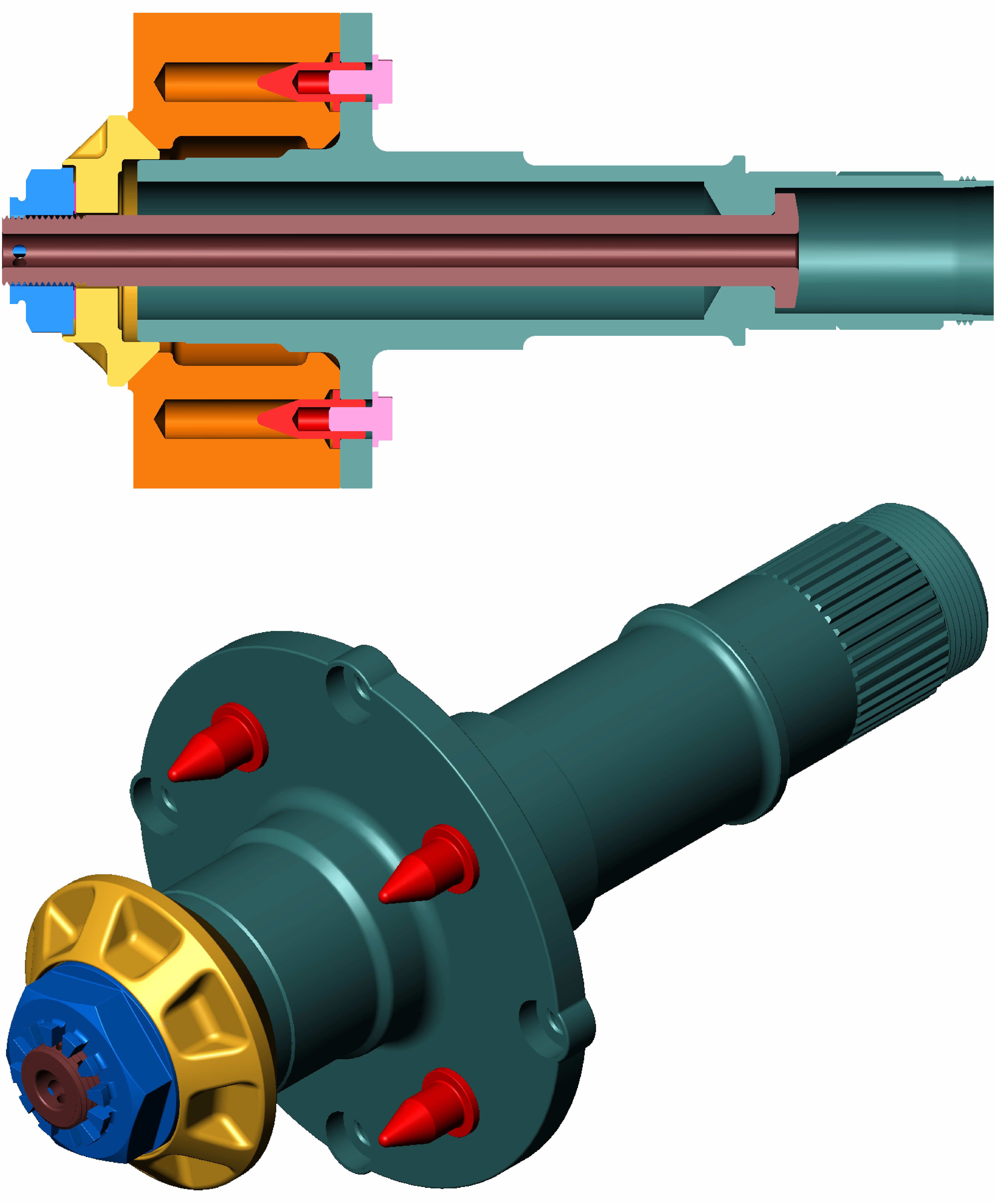

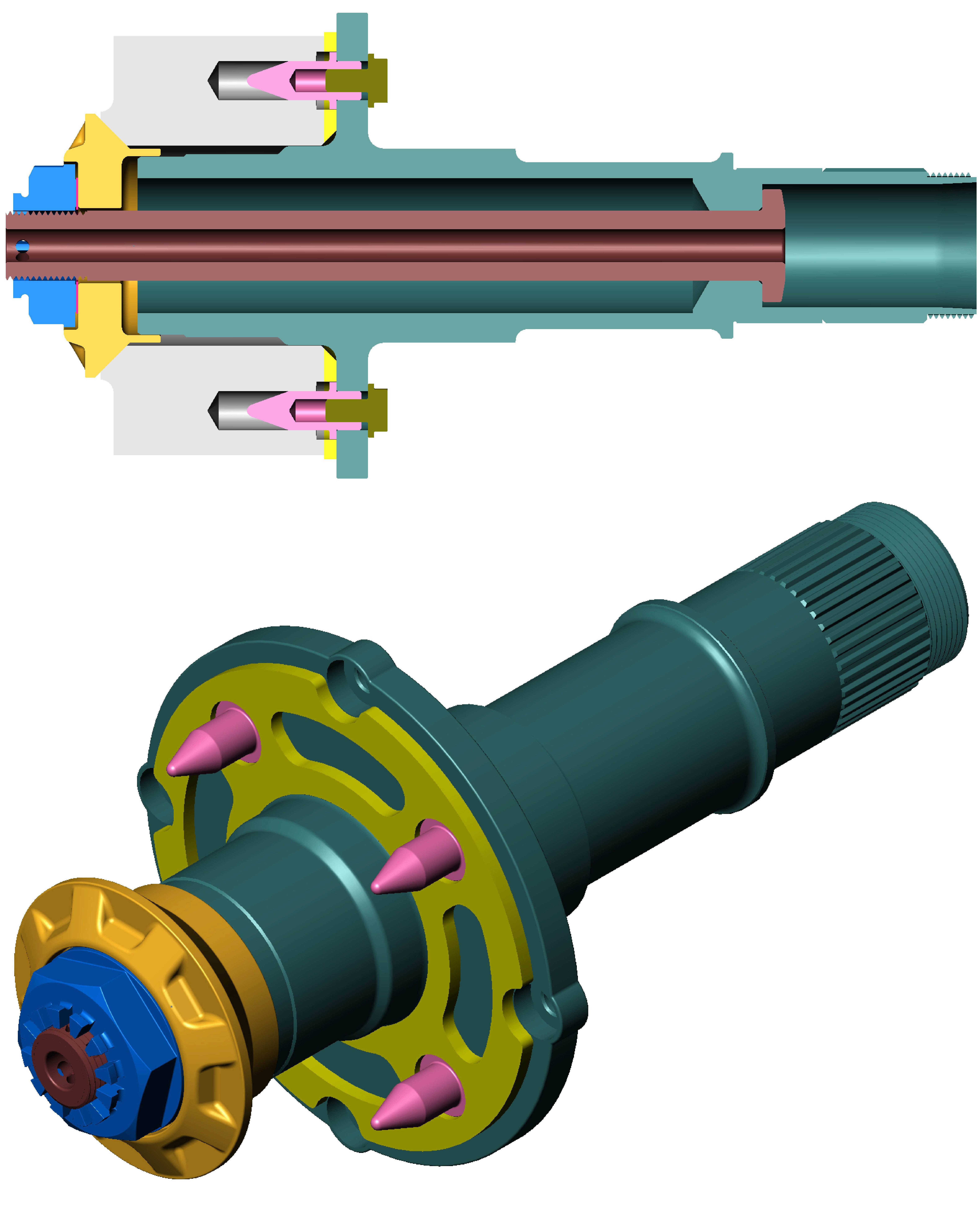

Below is a 3D Assembly Model of the ORIGINAL HONDA DESIGN:

Below is a 3D Assembly Model of the MY MODIFIED DESIGN with bored out wheel, longer wheel pins, spacer between the wheel and axle, and a custom centerlock spacer.

Extended wheel pins alongside a Honda original. These are both threaded for 7mm x 1 mm/thread and take the stock bolts. The new/longer pins still need to be zinc plated & chromate converted. The longer pins do not cause any bottoming out issues on the original Honda wheel with the spacer taken out.

Wheel spacer, 3.18mm thick. Designed to go on the outside of the shoulder of the (new/longer) wheel pins. This was cut out of sheet using water jet with the 45 degree taper on the ID subsequently cut on a lathe. The 36.4 g marked on the spacer was from the solid model calculation using 2700 kg/m3 density. Weight checks out. Number don't lie, people do.

The side shown in the picture goes towards the axle. The bevel is to clear the radius of the axle.

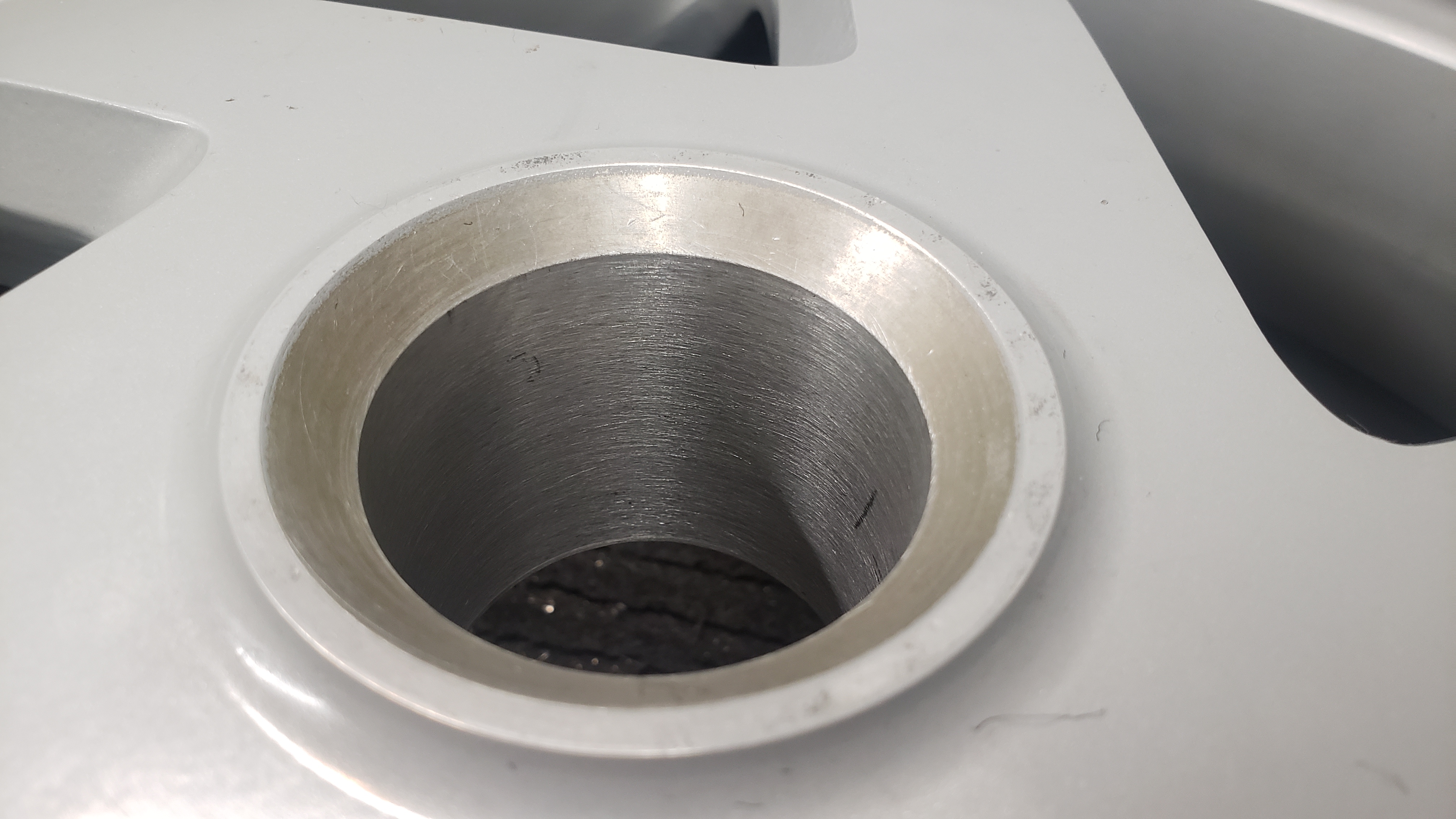

A good look at the wheel after being bored out to match the RC30 wheel bore. This was done with a boring bar in a vertical mill. The width of the taper is now very close to that of the stock Honda wheel, just a hair narrower. IT looks like a lot of material was removed but the middle part only had about 0.022" removed n the radius.

And here is a picture before being bored out, just as Brembo had intended the wheel to look.

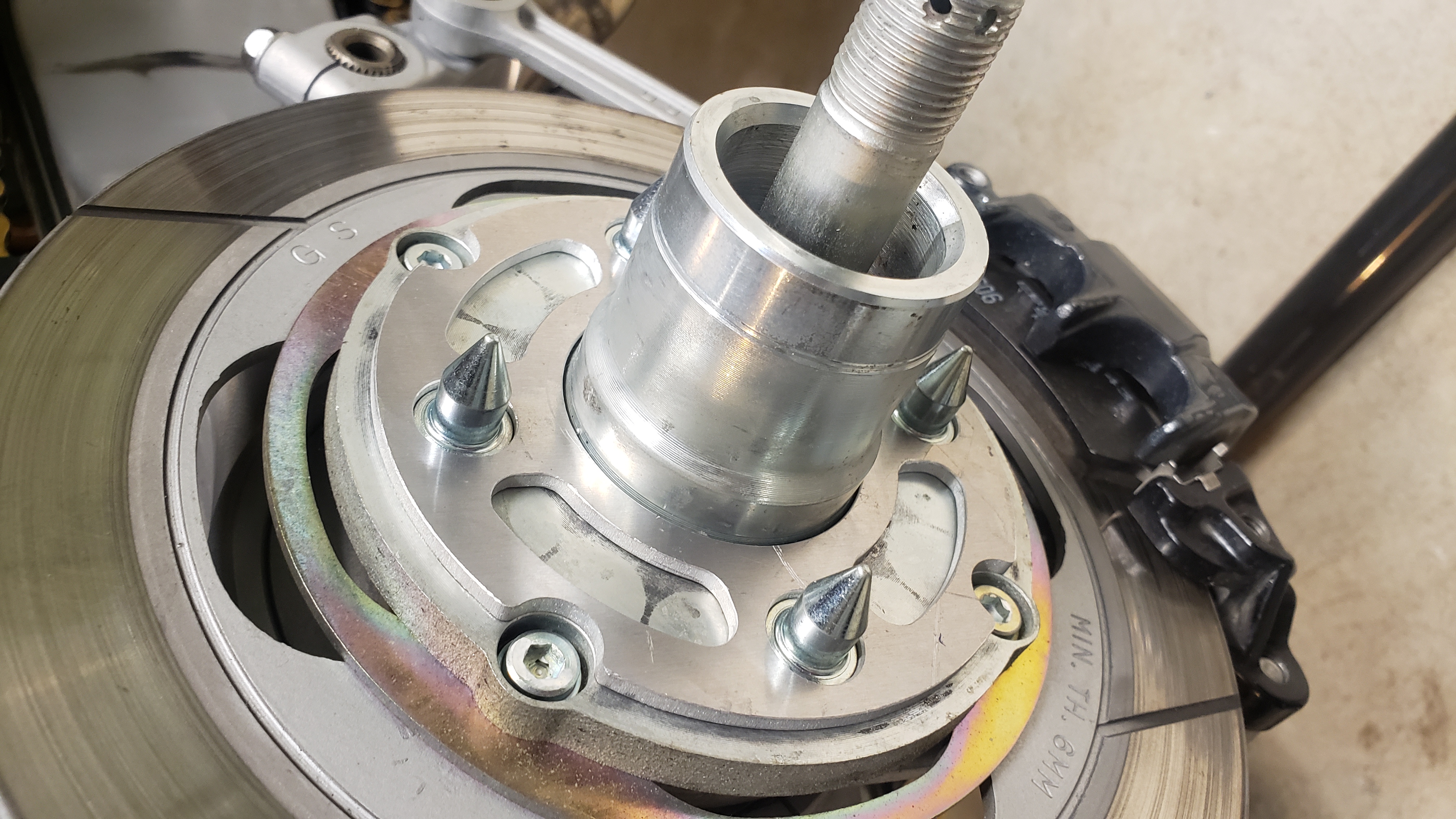

A look at the wheel spacer. Fits like a glove. Those are still the original/short Honda wheels pins in the picture and will be replaced by longer ones. The cutouts at the brake disc bolts and the radial slots are not necessary; did it only to keep weight to a bare minimum.

In the background you can also see where the 170/60-18 Dunlop Roadsmart on a stock wheel was hitting the swingarm a bit. It was the only tire & wheel put on this bike since it was built. I know this is what did it, I built this bike.

Showing the bored out wheel sitting tight against the 3.18mm (1/8") spacer. You can see how a stock centerlock spacer will fail to register on the large OD of the axle.

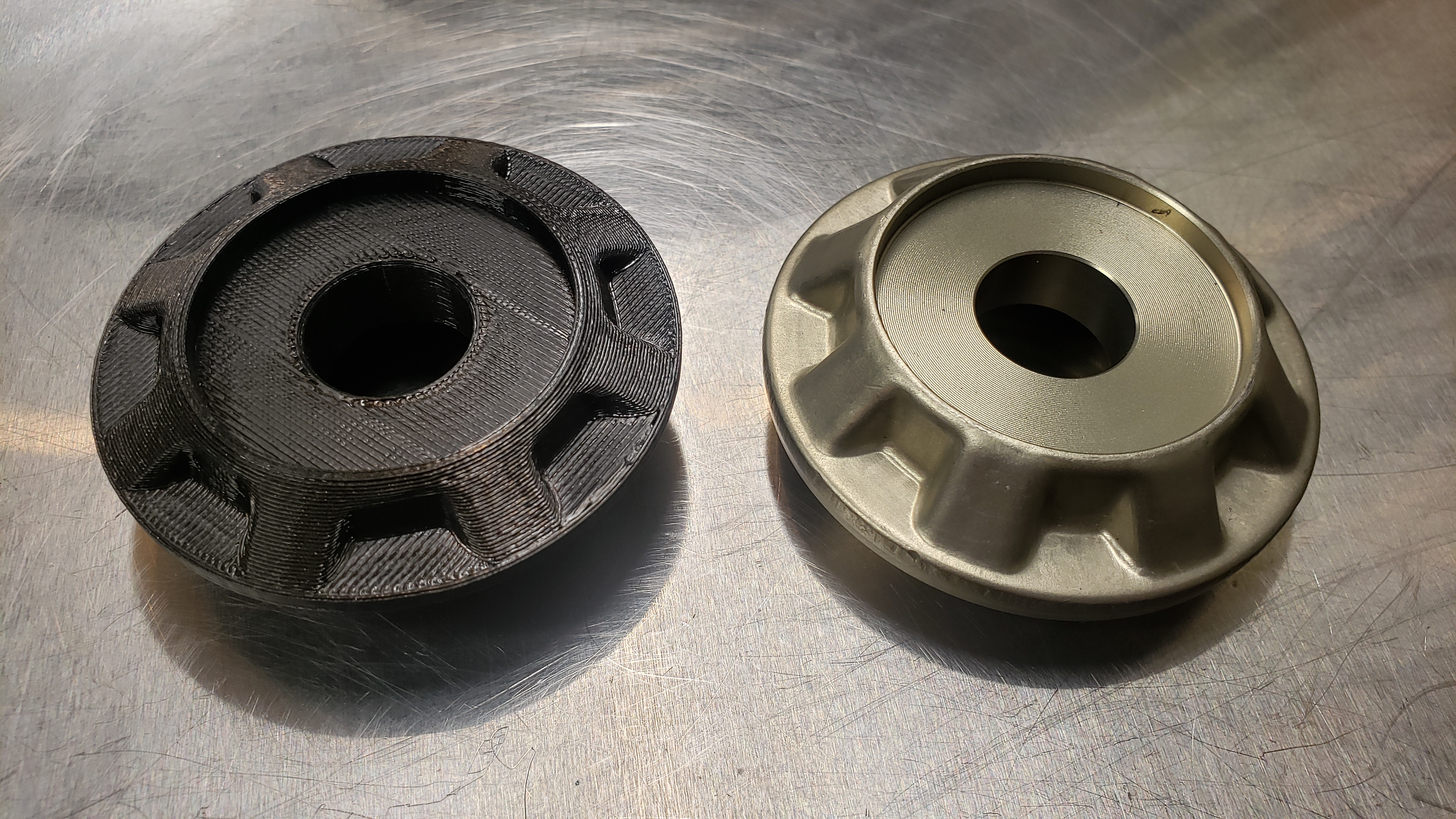

A stock Honda centerlock spacer and a prototype 3D print of my centerlock spacer. You can see how it will reach in and grab the axle. Mine will NOT be made from aluminum.

One last check on the castellated nut depth and some other clearances. Everything looks good so the 3D model is ready to be turned into metal.

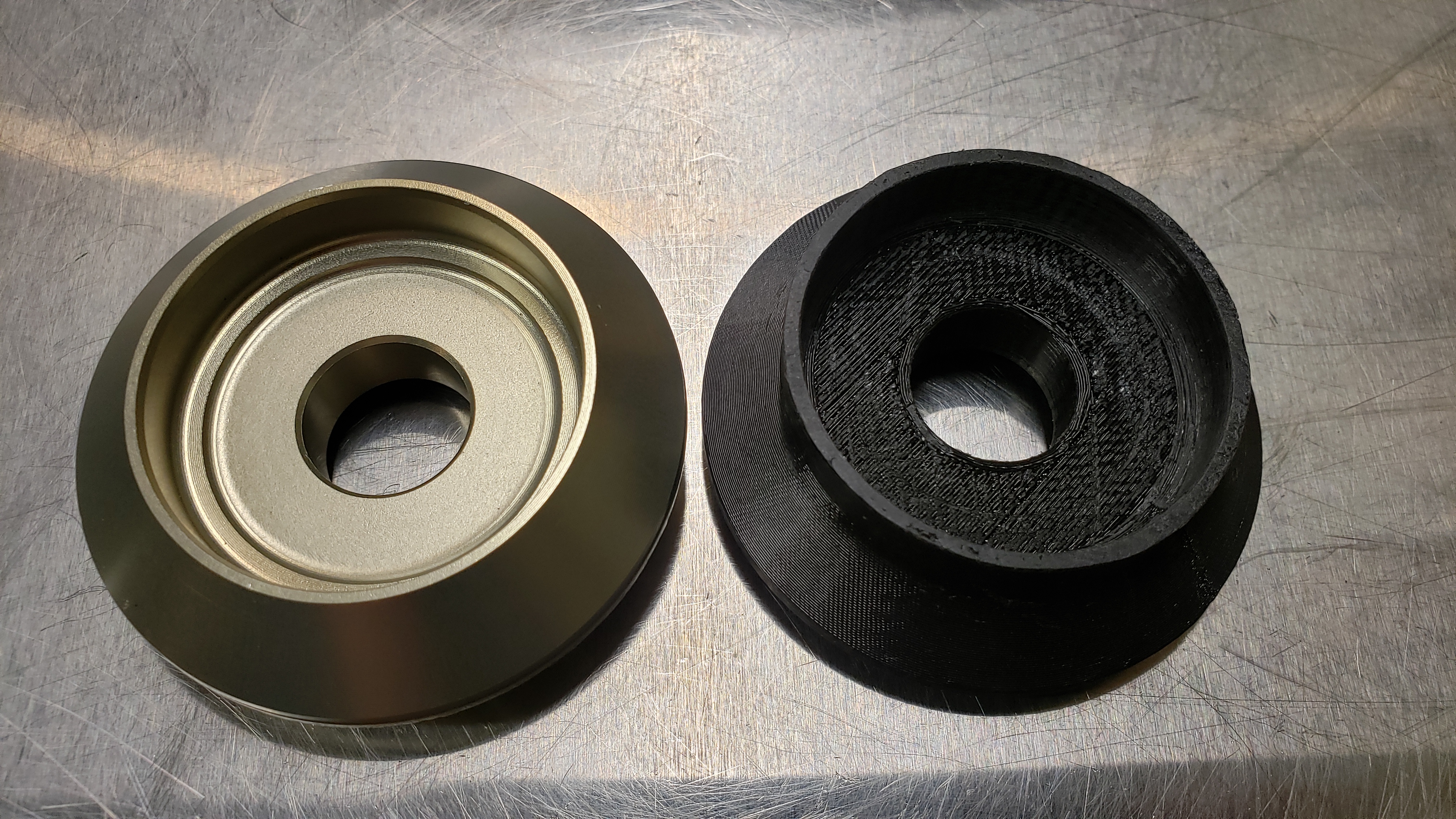

3D Model turned into metal on the lathe (most surfaces) and the CNC mill (the top surface). Weighs a few grams more than calculated in the solid model. These two pictures are metal in the raw.

.

Here are the completed parts with some of them zinc plated with a yellow dichromate conversion finish. I may anodize the wheel spacer but it really isn't necessary.

Some drawings I did to help during fabrication. I purposely removed some dimensions because this is going on the innerweb and we don't want kids to get hurt by blindly copying my design.

Materials, as always, are critical!

Here is another guy doing a similar wheel conversion using a 916 wheel. He has a different spacer thickness. He used a 2mm spacer but I stand by the 2.95mm using the wheels I had in front of me that day. He appears to have also made his own centerlock spacer. Can't tell if it is merely shallower or shallower and grabs the OD of the axle like mine. Doesn't sound like he extended the pins but there is not a lot of detail on anything. He abandoned the pro-squat linkage so did not have to deal with clearance to the link arm as I discussed above.